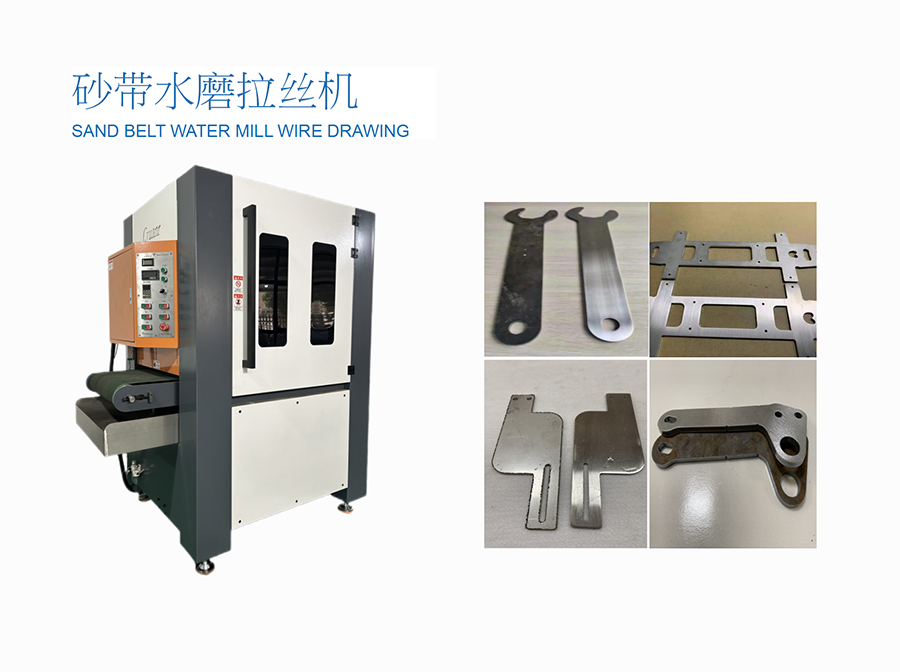

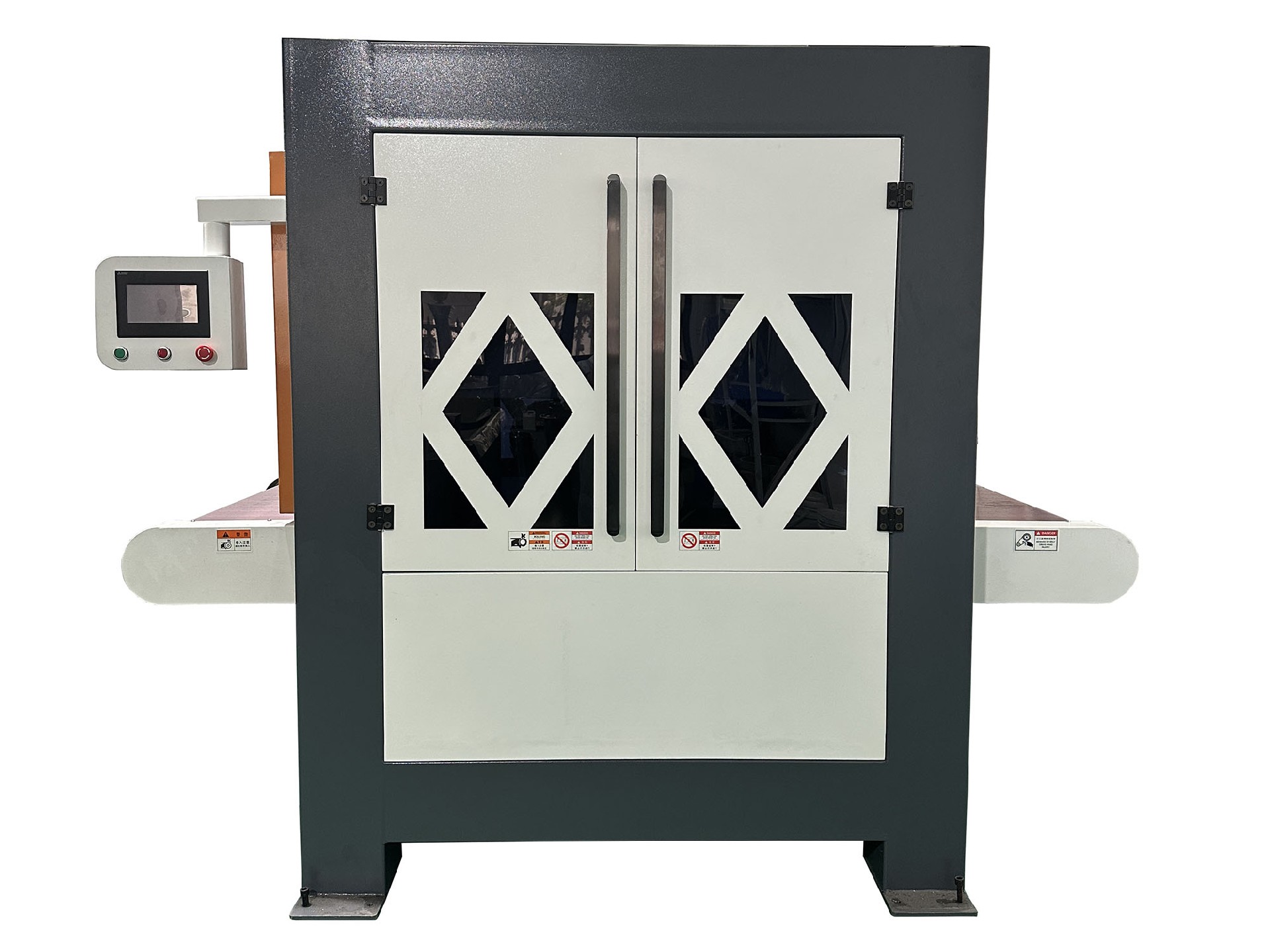

Chamfer and deburring machine

Purpose performance

The equipment is specifically designed to remove burrs such as burrs, hanging slag, and sharp edges from workpieces on the same plane or near the same plane, such as cutting burrs with saws, plasma cutting or laser cutting sintering hanging slag, CNC computer gong machining burrs, ordinary punch or CNC stamping sharp edges, etc. Linear machining, with multiple sets of sanding wheels rotating, rotating, and alternating, can truly and uniformly remove burrs and chamfers on the outer surface and hole edges of the parts at once. When deburring the product, the processing time can be set according to the size of the burrs to adjust the conveying speed (the conveying speed is adjusted by the frequency converter). After the product is inserted, the output is automatically completed, with continuous circulation, short cycle time, and high processing efficiency.

Equipment characteristics

1. When deburring, there is no cutting on the front of the product, which does not affect the product size and does not damage the coated sanding wheel through revolution and rotation,

2. Grind the surface contour of the workpiece 360 ° without dead corners to remove burrs, so that the burrs are quickly removed and the chamfer is uniform.

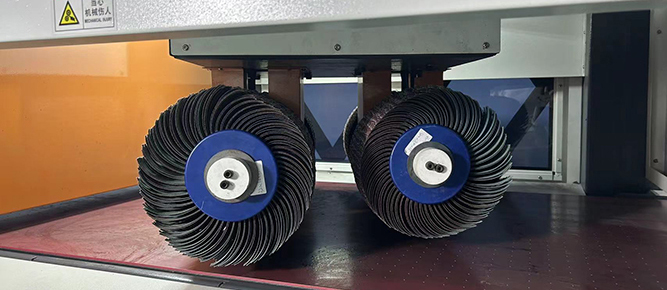

Working principle

Principle of Universal Roller Brush Mechanism

The deburring and rounding function is completed by the sanding wheel on the universal roller brush mechanism. The two pairs of sanding wheels of the universal roller brush mechanism are horizontally opposed, rotating in reverse at high speed, and rotating horizontally together under the action of the equipment revolution mechanism. The high-speed rotation of the sanding wheel generates centrifugal force to scrape and rub the contour edges of the workpiece. Combined with the overall revolution, the workpiece can achieve a universal and uniform chamfer at any position on the conveyor belt, making all contour edges of the product smooth and round, and obtaining a consistent R-angle.

Basic equipment parameters

1. Scope of equipment application: Suitable for laser cutting and stamping of flat plate parts, carbon steel plates, stainless steel plates, aluminum plates, copper plates, titanium alloys, various non-ferrous metals, coated metal plates, rubber and plastic materials, etc.

2. Equipment function: Batch processing of surface scratches, burrs, chamfers, blunting, and sharp edges removal for laser cutting, plate cutting, stamping cutting, water jet cutting, plasma cutting, and other workpiece surfaces

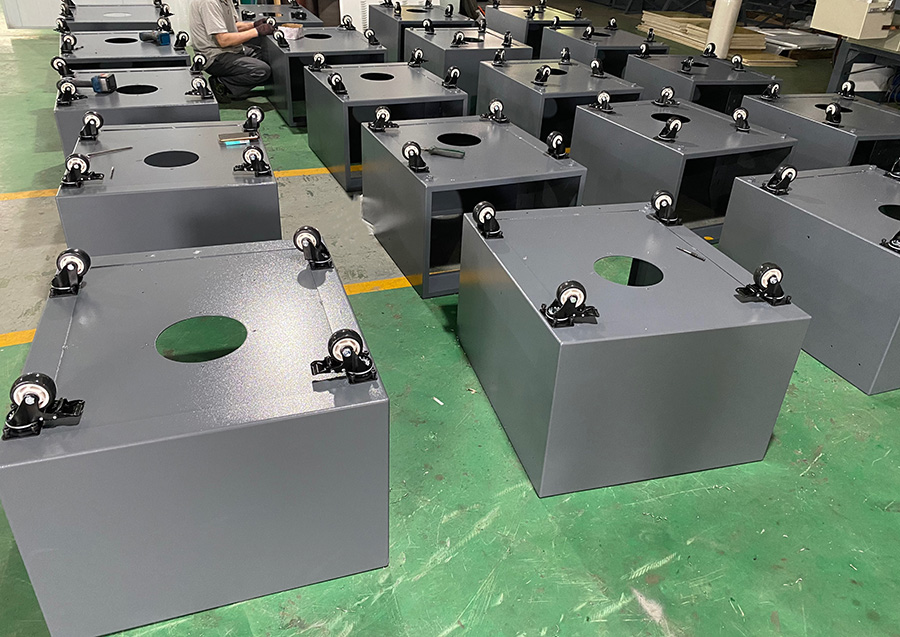

3. Equipment combination: Universal rolling brush single or multiple combined structures

4. Equipment processing width: 500mm, 800mm, 1000mm, 1300mm, 1500mm, 1600mm, 2000mm

5. Equipment processing thickness: 0.5-100mm

6. Conveying and feeding speed: 0.5-6m/min (variable frequency adjustable)