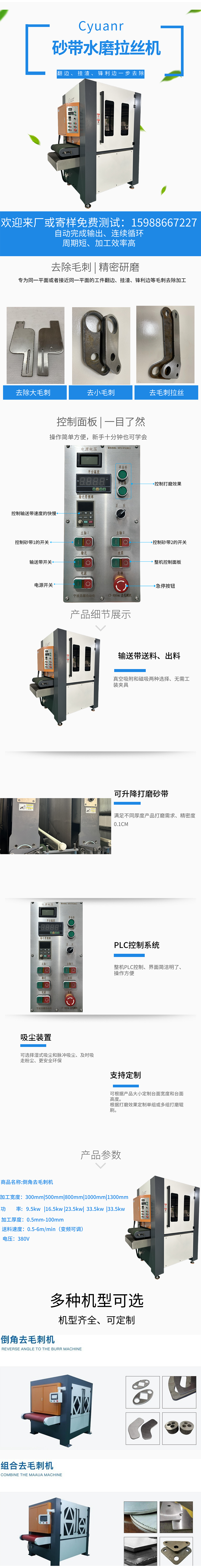

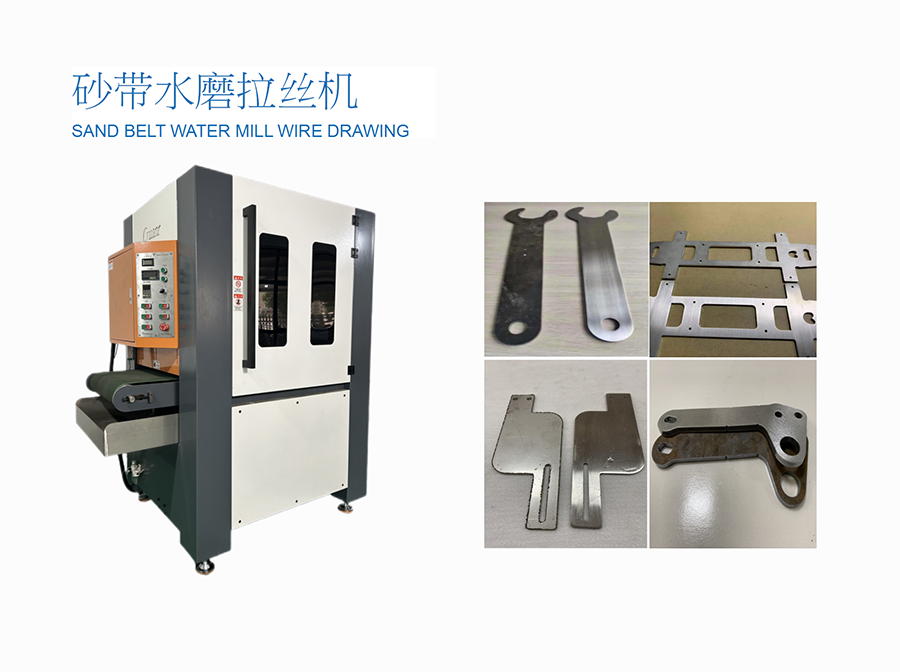

Sand belt water grinding wire drawing machine

Purpose performance

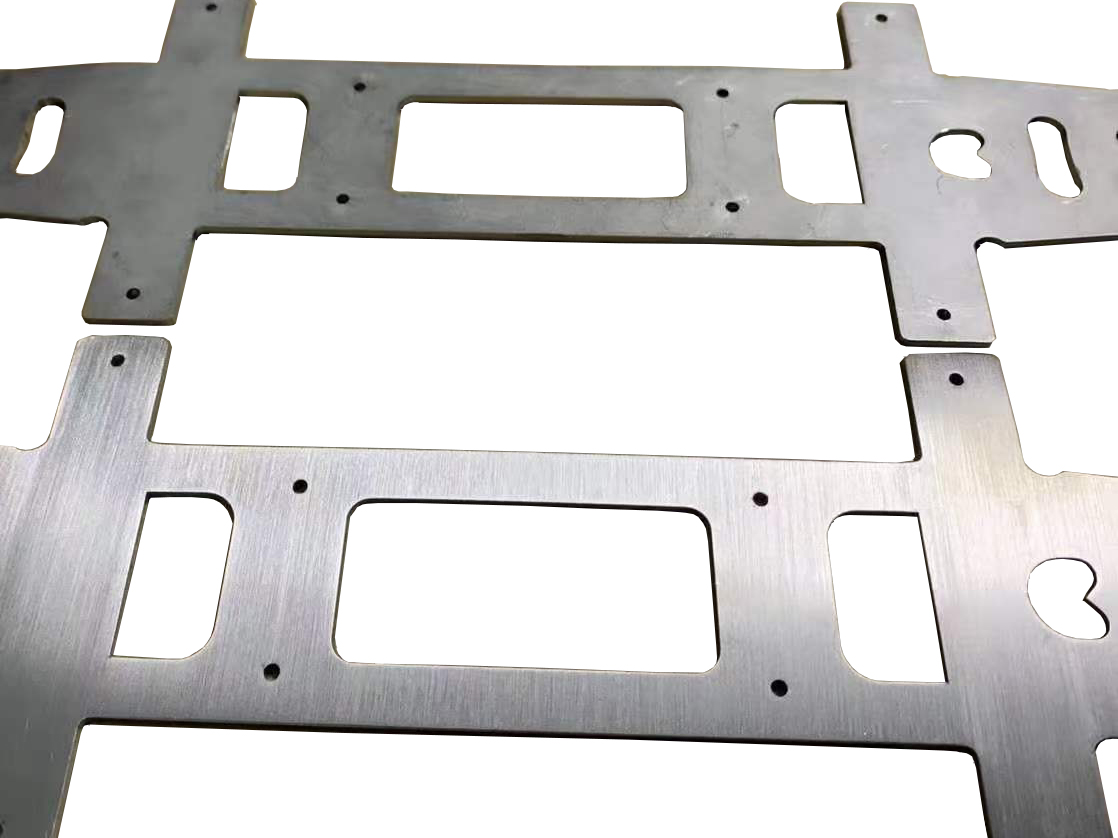

Suitable for deburring and wire drawing on the surface of stamping and laser cutting parts, used for both dry and wet purposes. It can be used for deburring metal flat surfaces such as various models of stainless steel, iron plate, copper, aluminum, etc

Equipment characteristics

1. Quickly remove large burrs, slag, and surface wire drawing from the workpiece.

2. Equipped with advanced technologies such as automatic correction of sand belts and quick replacement of sand belts, the equipment adopts platform automatic lifting and automatic correction of sand belts.

Operational principle

Principle of Wide Belt Sanding Mechanism

The wide sand belt position is driven by a motor to rotate the sand belt at high speed, which is used for pre-treatment of large burrs. Multiple sets of sand belts can be selected for surface wire drawing.

Basic equipment parameters

1. Scope of equipment application: Suitable for laser cutting and stamping of flat plate parts, carbon steel plates, stainless steel plates, aluminum plates, copper plates, titanium alloys, various non-ferrous metals, coated metal plates, rubber and plastic materials, etc.

2. Equipment function: Batch processing of surface pre grinding, wire drawing, polishing, scratch removal, deburring, etc. for laser cutting, plate cutting, stamping cutting, water knife cutting, plasma cutting, and other workpiece surfaces.

3. Equipment combination: single or multiple combination structures of wide sand belts.